Box Design Upgrades

Create the unforgettable unboxing experience

The box upgrades are structural parts designed to be added to the basic box models to enhance their functionality and appearance. Turning the box tray into something else, or using ribbons for brilliance and ease, will help you to add an invaluable quality to the users’ interaction with your products or promotional materials.

We offer ready design solutions for easy and clever ways to enhance the performance of your chosen box.

Luxurious and convenient fabric elements

Upgrading a basic box with a ribbon helps in two ways. The ribbon decorates the box on the outside or on the inside. It also is a structural element that enhances the box’s functionality.

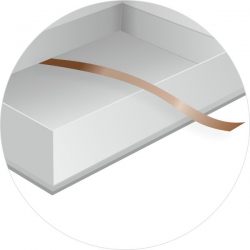

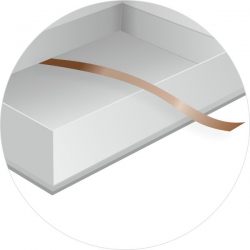

Ribbon Lift

This element consists of a single ribbon, permanently glued to the box bottom. It helps to take out the box contents without effort.

The length of the ribbon piece varies according to the box size and to the client’s requirements. The ribbon width that we recommend is 10 mm.

The commonly used ribbon types are satin and grosgrain. Those two types allow for hot processing of the loose ends to avoid fraying.

Applicable for: Book Style Box, Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

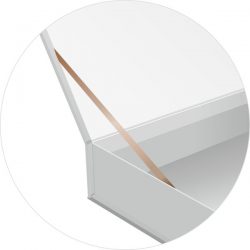

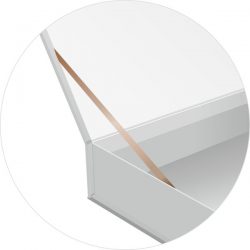

Ribbon Stop

This box component is called a ribbon stop for its function to limit the movement of a hinged lid. It is permanently glued in two places, one on the box tray and one on the lid. We use wisely additional paper elements to hide the two glued ribbon ends.

The length of the ribbon piece varies according to the box size and to the client’s requirements. The ribbon width that we recommend is 5 or 10 mm.

The commonly used ribbon types are satin and grosgrain. Those two types allow for hot processing of the loose ends to avoid fraying.

Applicable for: Rigid Tray Book Style Box, Economy Cover Box, 4&5 Panels Cover Box.

Ribbon Pull

The ribbon pull is a useful embellishment of the hard cover boxes. It makes it possible to open the hinged lid without effort. The doubled ribbon piece glued end is inserted under the binding material of the hard cover’s inner side.

The length of the ribbon piece varies according to the client’s requirements. The ribbon width that we recommend is 10 or 20 mm.

All ribbon types are suitable for this element.

Applicable for: 3-Panel Economy Cover Box, 4&5 Panels Cover Box.

Ribbon Lift

This element consists of a single ribbon, permanently glued to the box bottom. It helps to take out the box contents without effort.

The length of the ribbon piece varies according to the box size and to the client’s requirements. The ribbon width that we recommend is 10 mm.

The commonly used ribbon types are satin and grosgrain. Those two types allow for hot processing of the loose ends to avoid fraying.

Applicable for: Book Style Box, Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

Ribbon Stop

This box component is called a ribbon stop for its function to limit the movement of a hinged lid. It is permanently glued in two places, one on the box tray and one on the lid. We use wisely additional paper elements to hide the two glued ribbon ends.

The length of the ribbon piece varies according to the box size and to the client’s requirements. The ribbon width that we recommend is 5 or 10 mm.

The commonly used ribbon types are satin and grosgrain. Those two types allow for hot processing of the loose ends to avoid fraying.

Applicable for: Rigid Tray Book Style Box, Economy Cover Box, 4&5 Panels Cover Box.

Ribbon Pull

The ribbon pull is a useful embellishment of the hard cover boxes. It makes it possible to open the hinged lid without effort. The doubled ribbon piece glued end is inserted under the binding material of the hard cover’s inner side.

The length of the ribbon piece varies according to the client’s requirements. The ribbon width that we recommend is 10 or 20 mm.

All ribbon types are suitable for this element.

Applicable for: 3-Panel Economy Cover Box, 4&5 Panels Cover Box.

Sustainable inventions inside the box

The tray inserts are undeniably the most powerful instrument for making the box special. They will fit your luxury product or promotional materials to the best extent. All inserts are made to order, in custom shapes and sizes. The one thing they have in common is their sustainable origin. No plastic elements are included in the inserts offered by nPack.

Interior Tray

This exclusive concept by nPack consists of two parts. One part is the smaller tray which is positioned centrally inside the box The other part is a supporting level element around the small tray that fixes its position. Optionally, the two parts can be glued to each other and to the outer tray.

The small tray is made from solidboard, 1 to 2 mm thick and covered with a thin binding material. The levelling part is made from thick paperboard. The two parts may differ in colour and texture.

Adding a ribbon lift is an option for ease of use and extra decoration.

Applicable for: Rigid Tray Book Style Box, Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

Interior Lid

Another design solution by nPack is the Interior lid, whose basic purpose is the so-called wow effect. What’s more, its presence adds one more surface for a brand message. Apart from the lift-off lid, this solution includes support elements fixed to the inside of the box.

All elements use 1 to 2 mm solidboard as core material. They are wrapped in a thin binding material which allows for colour combinations.

Adding a ribbon pull is an option for ease of use and extra decoration.

Applicable for: Rigid Tray Book Style Box, Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

Dividers

The variety of dividers that can be used inside a box is really great. nPack speciality is the divider made from solidboard and processed via v-grooving. Other styles and materials are possible too. All dividers are custom design solutions.

The most preferred divider material is the solidboard, typically 2 mm thick.

Black or white, dyed-through solidboard is the common material choice. Optionally, stock grey solidboard can be used in combination with a binding material.

Applicable for: Book Style Box, Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

Custom Inlay

Inlay options exist to cushion a product or to change the inner shape of a box. True to nPack’s environment philosophy, all custom inlays that we create use paper and board only. Endless types of nesting, levelling, sliding or blocking elements can be developed by our designers according to customers’ needs.

The most preferred inlay material is the solidboard, typically 2 mm thick.

Black or white, dyed-through solidboard is the common material choice. Optionally, stock grey solidboard can be used in combination with a binding material and paperboard.

Applicable for: Book Style Box, Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

Interior Tray

This exclusive concept by nPack consists of two parts. One part is the smaller tray which is positioned centrally inside the box The other part is a supporting level element around the small tray that fixes its position. Optionally, the two parts can be glued to each other and to the outer tray.

The small tray is made from solidboard, 1 to 2 mm thick and covered with a thin binding material. The levelling part is made from thick paperboard. The two parts may differ in colour and texture.

Adding a ribbon lift is an option for ease of use and extra decoration.

Applicable for: Rigid Tray Book Style Box, Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

Interior Lid

Another design solution by nPack is the Interior lid, whose basic purpose is the so-called wow effect. What’s more, its presence adds one more surface for a brand message. Apart from the lift-off lid, this solution includes support elements fixed to the inside of the box.

All elements use 1 to 2 mm solidboard as core material. They are wrapped in a thin binding material which allows for colour combinations.

Adding a ribbon pull is an option for ease of use and extra decoration.

Applicable for: Rigid Tray Book Style Box, Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

Dividers

The variety of dividers that can be used inside a box is really great. nPack speciality is the divider made from solidboard and processed via v-grooving. Other styles and materials are possible too. All dividers are custom design solutions.

The most preferred divider material is the solidboard, typically 2 mm thick.

Black or white, dyed-through solidboard is the common material choice. Optionally, stock grey solidboard can be used in combination with a binding material.

Applicable for: Book Style Box, Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

Custom Inlay

Inlay options exist to cushion a product or to change the inner shape of a box. True to nPack’s environment philosophy, all custom inlays that we create use paper and board only. Endless types of nesting, levelling, sliding or blocking elements can be developed by our designers according to customers’ needs.

The most preferred inlay material is the solidboard, typically 2 mm thick.

Black or white, dyed-through solidboard is the common material choice. Optionally, stock grey solidboard can be used in combination with a binding material and paperboard.

Applicable for: Book Style Box, Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

A special place for your gift or message

We offer several styles of extra elements to fix a folded paper document, an envelope, any kind of card and many other flat objects. Custom-made from paper and paperboard, these design solutions can be adapted to different box styles and serve different purposes.

Sleeve Pocket

The sleeve pocket is a paperboard element with side openings on both ends. It is mostly suitable for any kind of narrow, flat-folded paper sheets such as greeting letters, cards, etc. It can be permanently glued to the hard cover. Paper pockets are made to order and their shapes and sizes are customisable.

The sleeve pockets are made from paper of 250-300 gsm thickness and often involve the utilisation of paper offcuts.

For ease of use, we offer thumbholes at one or two positions.

Applicable for: Book Style Box, Economy Cover Box, 4&5 Panels Cover Box.

Paper Wallet

The paper wallet is a paperboard element with an opening on the top long side. It is suitable for cards and paper sheets of any thickness and can even fit a booklet. It can be permanently glued to the hard cover.

The paper wallets are made from paperboard of 300-350 gsm thickness. Paper offcuts can be used for their production.

For ease of use, we offer a thumbhole on the upper side. The wallets can be produced with or without capacity.

Applicable for: Book Style Box, Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

Mounting Corners

The mounting corner set consists of two or four small triangular pocket-like elements permanently attached to the box. The corners are strong enough to hold light- to heavy-weight flat objects. The size and positioning of the corners are customisable.

The mounting corners are made from paper of 150-250 gsm thickness. Their production can utilise paper offcuts.

They are only offered in sets with nPack’s boxes and are always fixed.

Applicable for: Book Style Box, Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

Sleeve Pocket

The sleeve pocket is a paperboard element with side openings on both ends. It is mostly suitable for any kind of narrow, flat-folded paper sheets such as greeting letters, cards, etc. It can be permanently glued to the hard cover. Paper pockets are made to order and their shapes and sizes are customisable.

The sleeve pockets are made from paper of 250-300 gsm thickness and often involve the utilisation of paper offcuts.

For ease of use, we offer thumbholes at one or two positions.

Applicable for: Book Style Box, Economy Cover Box, 4&5 Panels Cover Box.

Paper Wallet

The paper wallet is a paperboard element with an opening on the top long side. It is suitable for cards and paper sheets of any thickness and can even fit a booklet. It can be permanently glued to the hard cover.

The paper wallets are made from paperboard of 300-350 gsm thickness. Paper offcuts can be used for their production.

For ease of use, we offer a thumbhole on the upper side. The wallets can be produced with or without capacity.

Applicable for: Book Style Box, Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

Mounting Corners

The mounting corner set consists of two or four small triangular pocket-like elements permanently attached to the box. The corners are strong enough to hold light- to heavy-weight flat objects. The size and positioning of the corners are customisable.

The mounting corners are made from paper of 150-250 gsm thickness. Their production can utilise paper offcuts.

They are only offered in sets with nPack’s boxes and are always fixed.

Applicable for: Book Style Box, Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

Sliding designs with a unique look

Sleeves are outer paper bands that cover the box on 4 sides. While the Full Sleeve covers the entire length of the box, the Banderole and the Lift-off Band provide only partial coverage. The design and scoring of the sleeves allow them to fit the box as tightly as the customer requires.

Full Sleeve

The full sleeve is an additional wrap of the entire box which leaves only the two smallest box sides visible. By covering most of the surface of the box, it becomes a great printing area which needs a much smaller printed media compared to the whole box.

The full sleeve is usually a printable material, up to 300 gsm in thickness.

The full sleeve colour and texture may differ from the box outside to create a contrasting effect.

Applicable for: Book Style Box, Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

Banderole

Similar to the full sleeve, the banderole is a partial wrap of the box. It is only a stripe of paper which allows for the most part of the box to remain visible. It is a great idea for a printing surface which needs a small printed media compared to the whole box.

The banderole is an element that can use paper offcuts from printable media up to 300 gsm in thickness.

The banderole colour and texture may differ from the box outside to create a contrasting effect.

Applicable for: Book Style Box, Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

Lift-Off Band

The lift-off band is a clever invention of nPack’s team. It is applied to a set of boxes, where one box goes inside the other to save transport and storage costs. Typically, this band has a tear-off strip which turns it easily into a handle to take out one box outside of the other.

The lift-off band is an element that can use paper offcuts from any media up to 300 gsm in thickness.

The band’s colour and texture may differ from the box outside to create a contrasting effect.

Applicable for: 3-Panel Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

Full Sleeve

The full sleeve is an additional wrap of the entire box which leaves only the two smallest box sides visible. By covering most of the surface of the box, it becomes a great printing area which needs a much smaller printed media compared to the whole box.

The full sleeve is usually a printable material, up to 300 gsm in thickness.

The full sleeve colour and texture may differ from the box outside to create a contrasting effect.

Applicable for: Book Style Box, Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

Banderole

Similar to the full sleeve, the banderole is a partial wrap of the box. It is only a stripe of paper which allows for the most part of the box to remain visible. It is a great idea for a printing surface which needs a small printed media compared to the whole box.

The banderole is an element that can use paper offcuts from printable media up to 300 gsm in thickness.

The banderole colour and texture may differ from the box outside to create a contrasting effect.

Applicable for: Book Style Box, Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

Lift-Off Band

The lift-off band is a clever invention of nPack’s team. It is applied to a set of boxes, where one box goes inside the other to save transport and storage costs. Typically, this band has a tear-off strip which turns it easily into a handle to take out one box outside of the other.

The lift-off band is an element that can use paper offcuts from any media up to 300 gsm in thickness.

The band’s colour and texture may differ from the box outside to create a contrasting effect.

Applicable for: 3-Panel Economy Cover Box, 4&5 Panels Cover Box, Lid & Base Box, Neck Box.

MOQ 100 pcs

Bespoke production

Luxury finishes

Looking for support from industry professionals?

Share the project specifics and product features you are considering and we will come back to you with comments and price options.